NEWEST-CCUS researchers explore potential to lift capture rates and generate heat for district heating

Dan Su discusses the team’s latest journal paper

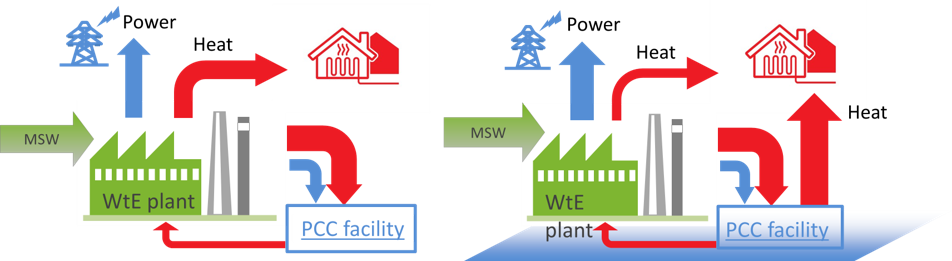

Results from modelling undertaken in NEWEST-CCUS show there is significant potential for heat recovery from the post-combustion CO2 capture (PCC) process on a Waste-to-Energy (WtE) plant to provide heat for District Heating (DH), according to a new paper published by the NEWEST-CCUS team.

“With advanced heat recovery, the energy utility factor of WtE plant could be higher than that for WtE plant without PCC,” it finds.

The paper, Thermal integration of waste to energy plants with post-combustion CO2 capture, is published in the journal Fuel. The study is built upon a series of modelling activities, with three representative WtE plant steam cycle configurations selected to integrate monoethanolamine (MEA) based post-combustion CO2 capture.

“The findings of this study provide valuable information for the future implementation of carbon dioxide capture technology in the WtE sector,” says Dan Su, part of the NEWEST-CCUS team at the University of Edinburgh and lead author of the paper.

NEWEST-CCUS is a three-year project, funded by the ERA-NET Accelerating CCS Technologies initiative, to assess the scale of the European market for CCUS technologies in the WtE sector. Waste-to-Energy is becoming an important application sector for carbon capture utilisation and storage (CCUS) due to its role in urban waste management and its inherent potential of achieving negative emissions. The project also explores the sector’s potential for such cumulative net carbon dioxide removals from the atmosphere.

Higher capture rates feasible

The project’s results also show that optimised process design can be used to enable ultra-high CO2 capture (99.72% in this study) to be achieved with only a marginal increase in specific reboiler duty when compared with 95% capture. The study also highlights the importance of differentiating carbon intensities for different product bases: electrical or thermal or waste, which are important when comparing WtE CCS with other carbon saving technologies.

“Net zero implies a deep decarbonisation and is changing the expectation of residual emissions from CCUS,” says Ms Su. “A 95% CO2 capture rate has become the new industry standard, and is pushing towards ultra-high CO2 capture that allows zero-residual emissions.”

Looking ahead, she says full life cycle assessments are necessary to understand the negative CO2 emission potential of this technology at larger system boundaries.

“Pilot plants are important to prove the technical feasibility and environmental benefit of this technology, and should be built as early as possible,” she adds. “Solutions of flexible operation of WtE-combined heat and power (CHP) plants with CCS into the future district heating networks needs to be further investigated early. Effective business models should support/offset the costs of installing low-carbon heat networks and CCS facilities.”

To find out more about the waste-to-energy sector and CCS, please join our webinar on Wednesday January 25, 2023. Dan Su will be one of the speakers, giving a presentation: A comparative assessment of CO2 capture technologies for the Waste to Energy sector.

Figure: Illustrative description of Advanced heat integration of PCC with WtE-CHP plant