Stuttgart puts oxy-fuel technology for waste-to-energy through its paces

NEWEST-CCUS partners at the University of Stuttgart are testing oxy-fuel technology for the combustion of solid recovered fuels, which is expected to be of value to operators of waste-to-energy plants.

Innovations in oxy-fuel combustion and carbon dioxide (CO2) capture will support the waste-to-energy sector’s decarbonisation ambitions while contributing to overall climate action within the energy sector.

Scientists at the German university’s Institute of Combustion and Power Plant Technology (IFK) are investigating the use of so-called fluidised bed (FB) systems for oxy-fuel combustion. In this process, fuel is burned in an oxygen-rich atmosphere to produce a more concentrated CO2 stream, which aids capture of the greenhouse gas from the flue stream.

In the first phase of IFK’s experiments, different solid recovered fuels were combusted at a 20 kW electrically heated bubbling fluidised bed (BFB) facility. The results have shown that these fuels are suitable for both air and oxy-fuel combustion modes.

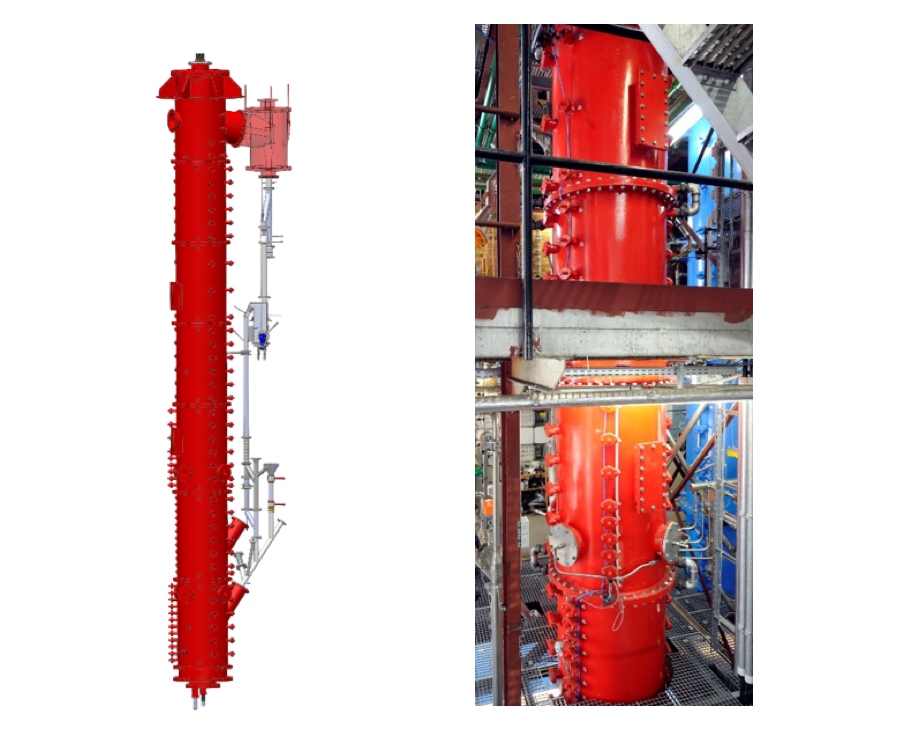

The next stage will see experiments scaled up at a 200 kW circulating fluidised bed (CFB) facility to demonstrate the technology in industrially relevant conditions. The scientists will undertake several 24-hour experimental campaigns, each day involving three back-to-back shifts.

This will allow for investigations over a wide range of operational conditions, with the first campaign scheduled for the end of this year.

The University of Stuttgart is one of Germany’s nine leading technical universities, with highly ranked programmes in engineering. The IFK has more than 50 years of expertise in energy research, including gaseous, liquid and solid fuels and associated technologies.

Graphic: Left, CAD drawing of IFK’s 200 kW CFB oxy-fuel combustor and, right, general overview of the pilot reactor